Color-coated steel sheet

Product thickness: 0.12-1.2mm

Product width: 600-1250mm

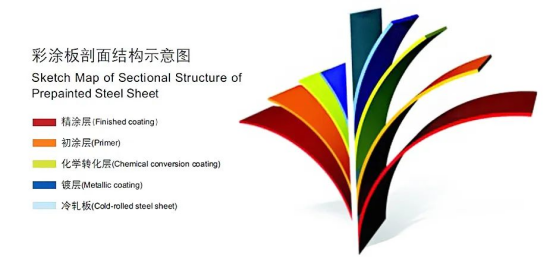

Color-coated steel sheet is also called color-coated sheet, color plate, color-coated coil, color steel coil, etc. What we usually call color-coated steel sheet is a product made of galvanized sheet as the substrate, surface pre-treatment, solvent-based paint applied by roller coating, baking and cooling.

Color-coated steel sheet is also called color-coated sheet, color plate, color-coated coil, color steel coil, etc. What we usually call color-coated steel sheet is a product made of galvanized sheet as the substrate, surface pre-treatment, solvent-based paint applied by roller coating, baking and cooling.

Color-coated steel sheet has the characteristics of high strength, beauty, high cost performance, and good anti-aging, anti-corrosion and processing performance. It has played a good role in replacing wood with steel, efficient construction, energy saving, and pollution prevention.

Color-coated plate coating classification

PE polyester color-coated plate

According to the type of coating and the surface effect of the coating, color-coated steel plates can be divided into PE polyester color-coated plates, HDP high weather-resistant color-coated plates, PVDF fluorocarbon color-coated plates, SMP silicon-modified polyester color-coated plates, sand surface color-coated plates, and reticulated color-coated plates.

Product introduction: PE polyester color-coated board is a metal paint color-coated board made by applying PE polyester paint on metal plate and then baking at high temperature.

Performance characteristics: good comprehensive outdoor durability and coating performance (flexibility, hardness, etc.); moderate chemical resistance; wide selection of colors and gloss; generally with epoxy paint as primer, excellent adhesion;

Applicable fields: medium cost, high cost performance, but its corrosion resistance, UV resistance and anti-powdering performance are average, only suitable for ordinary building roofs and walls, not suitable for severe corrosive environments.

PVDF fluorocarbon color-coated board

Product introduction: PVDF fluorocarbon color-coated sheet is a metal baking color-coated sheet made by coating a fluorocarbon coating with a fluorocarbon resin content of more than 70% on a metal plate and then baking it at high temperature.

Performance characteristics: The coating uses durable inorganic pigments and highly corrosion-resistant fluorocarbon resins, which can effectively resist the erosion of ultraviolet rays and corrosion factors; with a polyurethane primer with good flexibility, the coating has excellent processing performance, and the T-bend performance can be 0-2T; but due to uneven color spectrum, it is not suitable for overly bright colors; the service life can reach 20-25 years.

Applicable fields: Due to the high price, it is generally used in fields with high requirements for corrosion resistance and coating aging resistance.

SMP silicon-modified polyester color-coated sheet

Product introduction: SMP silicon modified polyester color coated sheet is a metal paint color coated sheet made by coating SMP silicon modified resin ester paint on metal plate and then baking at high temperature.

Performance characteristics: excellent outdoor durability (gloss and color retention); good coating performance: hardness, wear resistance, heat resistance; good chemical resistance; slightly less flexible than polyester; durability 10-15 years.

Applicable fields: medium to high cost, mainly suitable for outdoor buildings with high requirements for wear resistance and durability.

Sand surface color coated sheet

Product introduction: Sand surface color coated plate is a color coated plate that uses a high weather-resistant polyester coating containing frosted anti-scratch particles coated on galvanized, galvanized and other substrates.

Performance characteristics: The coating surface has an ultra-low gloss and a frosted feel close to nature;

Applicable fields: It is the main base material for the production of metal carved plates, and is widely used in indoor and outdoor insulation decoration of high-rise buildings, villas, and municipal landscape pavilions.

Reticulated color coated plate

Product introduction: Textured color-coated sheet refers to a color-coated sheet coated on galvanized, galvanized, cold-rolled and other substrates with a high weather-resistant polyester coating with a textured effect on the surface after drying.

Performance characteristics: The surface of the textured color-coated sheet has a textured or fabric-like effect on the touch, and is visually low-light. It does not have the stiff feeling of ordinary color-coated sheets and is closer to nature.

Application areas: Mainly used in color steel antique tiles and exterior wall decoration on the roofs of civil buildings, villas, etc.