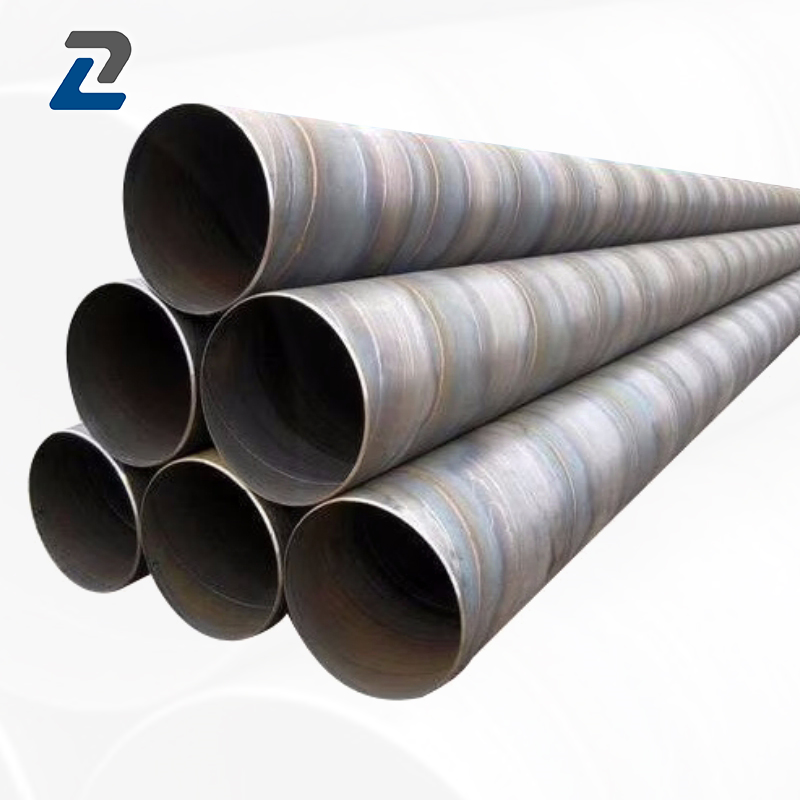

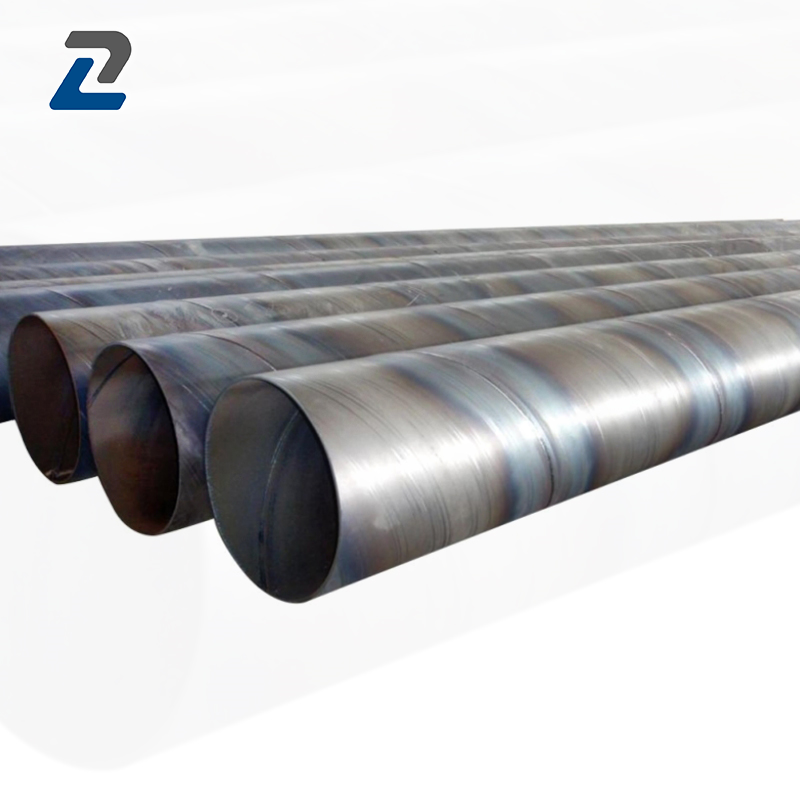

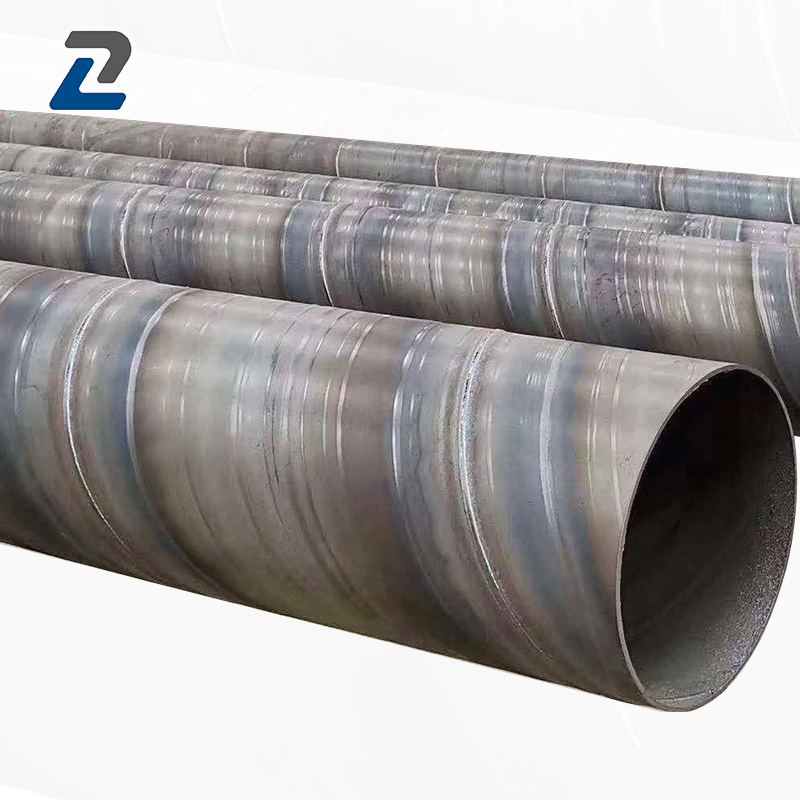

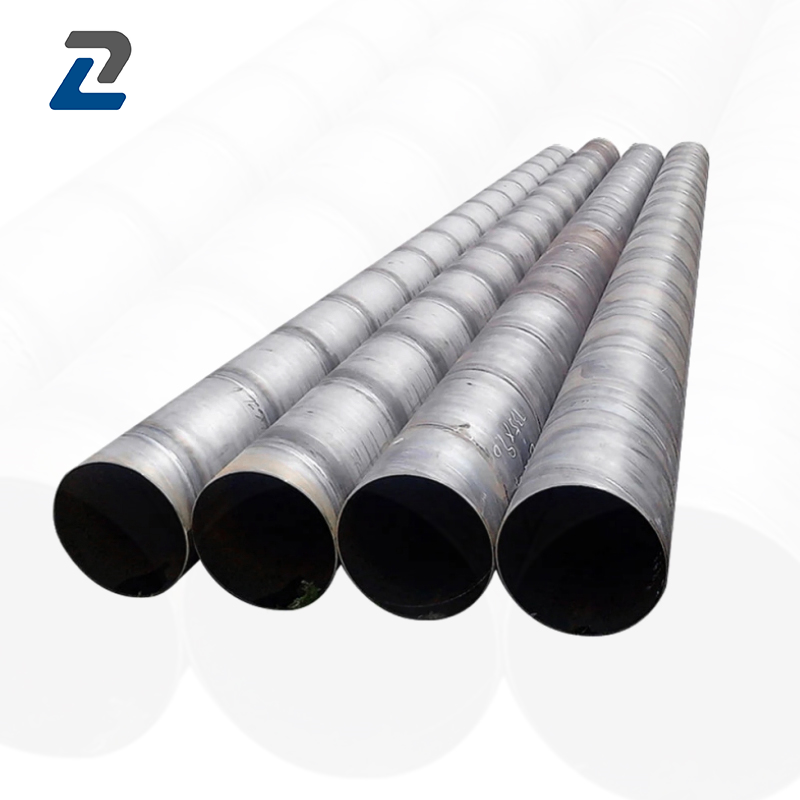

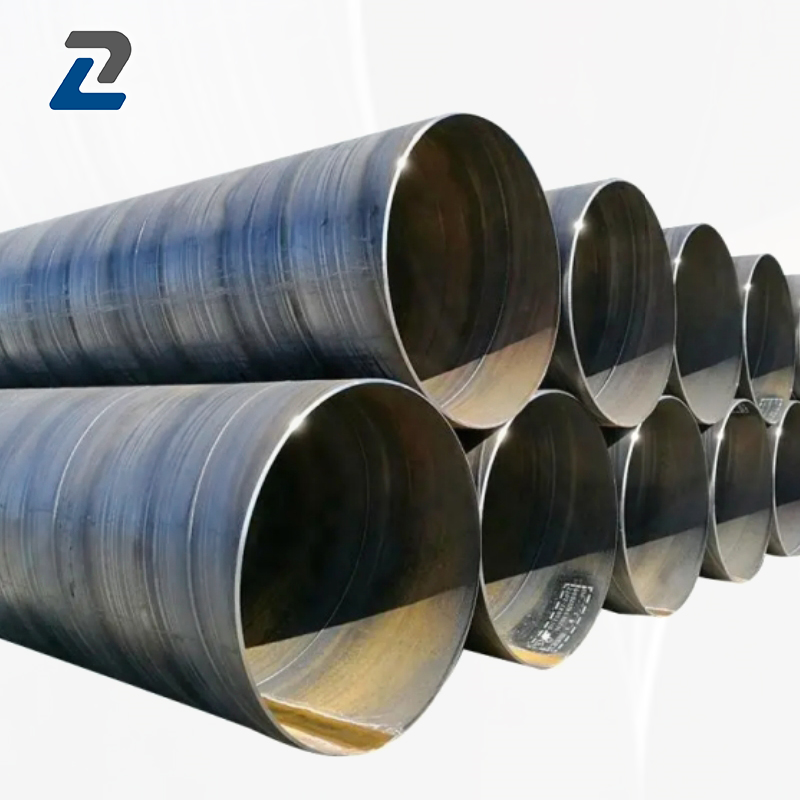

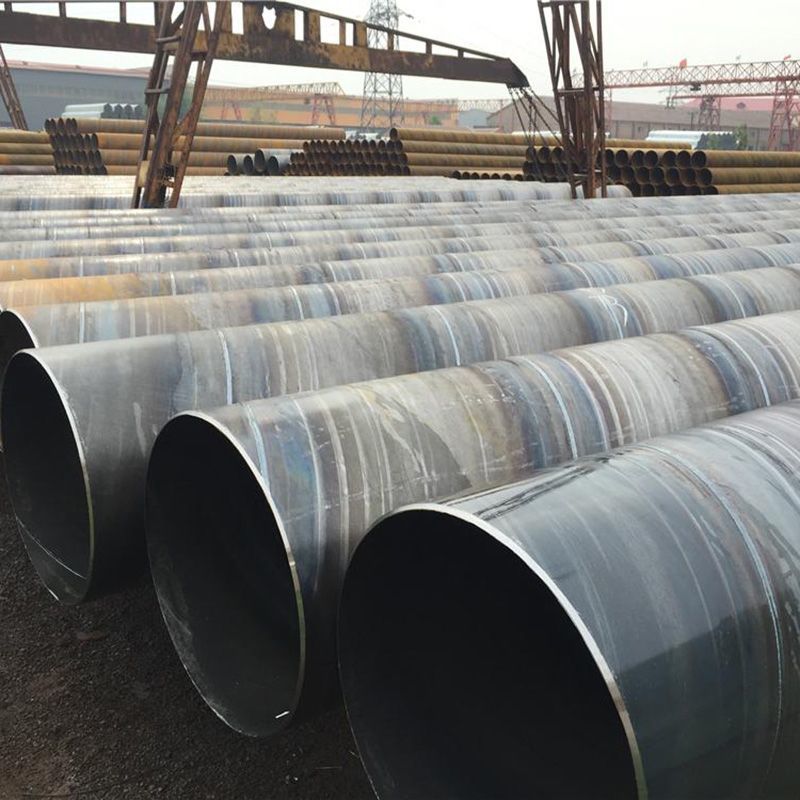

Spiral welded pipe: It is made by rolling low-carbon carbon structural steel or low-alloy structural steel strips into pipe blanks at a certain spiral angle (called forming angle), and then welding the pipe seams. It can be made of narrower pipes. Strip steel produces large diameter steel pipes. Its specifications are expressed as outer diameter * wall thickness. The welded pipe should ensure that the hydraulic pressure test, tensile strength and cold bending performance of the weld meet the regulations.

Product Parameters

|

Product Name |

Astm Carbon Steel Spiral Welded Tube Pipe Stm A179C A192 St35.8 Din17175 Erw Sch40 Spiral Welded Steel Pipe |

|

Standard |

ASTM A53, BS1387-1985, API 5L standard |

|

Technique |

Spirally Submerged Arc Welding(SSAW), Double Submerged Arc Welded (DSAW) |

|

Electronic Fusion Welded (EFW) |

|

|

Grade |

Q195 = S195 / A53 Grade A |

|

Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2 |

|

|

Q345 = S355JR / A500 Grade B Grade C |

|

|

Length |

5.8~12.0 m or as customized |

|

Outer Diameter |

219mm-2032mm |

|

Wall Thickness |

1.24mm-63.5mm |

|

Surface Treatment |

Prime quality (bared, oiled, color paint, 3LPE, or other anti-corrosive treatment) |

|

Inspection |

With Chemical Composition and Mechanical Properties Analysis; |

Product Specifications

| Specifications(mm) | Thickness(mm) |

| 1260*2440 | 1.5 |

| 1260*2440 | 2. 0 |

| 1260*6000 | 1.8 |

| 1260*6000 | 2. 0 |

| 1260*6000 | 2. 5 |

| 1260*6000 | 2. 75 |

| 1260*6000 | 2. 95 |

| 1260*6000 | 3. 5 |

| 1260*6000 | 3. 75 |

| 1260*6000 | 3. 95 |

| 1260*6000 | 4. 5 |

| 1260*6000 | 4. 75 |

| 1260*6000 | 4. 95 |

| 1260*6000 | 5. 5 |

| 1260*6000 | 5. 75 |

| 1260*6000 | 5. 75 |

| 1510*6000 | 8. 0 |

| 1510*6000 | 10 |

| 1510*6000 | 12 |

| 1510*6000 | 15 |

The above are the general items, for the special types, we can also meet your needs.

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

Applications

Spiral welded pipes are mainly used in water engineering, petrochemical industry, chemical industry, power industry, agricultural irrigation, and urban construction. Used for liquid transportation: water supply, drainage, sewage treatment engineering, mud transportation, ocean water transportation. Used for gas transportation: gas, steam, liquefied petroleum gas. Used as a structure: as a pile driving pipe, as a bridge; Pipes for docks, roads, building structures, ocean pile driving pipes, etc.

Project Cases

Additional Processing Technology

Spiral welded pipes can be cut, polished, welded, labeled, oiled, anti-corrosion and other processes.

Product Packaging

Product Transportation